Many industry analysts have designated 2018 as the Year of IoT in the Manufacturing industry. With the exponential growth of “smart factories,” the manufacturing industry is leading the Internet of Things (IoT) revolution, with benefits including increased efficiency, customer alignment, and vast, new data which can be used for new revenue sources. All of which is a part of the digital transformation occurring in manufacturing. Some industry leaders are calling this the Fourth Industrial Revolution, or Industry 4.0, following the steam engine, the conveyor belt, and the first phase of IT and automation.

Until recently, most manufacturers have been reluctant to adopt IoT, despite the vast benefits it offers. Both Frost and Sullivan and IDC cite several challenges, which include:

- Inability of IoT providers to provide complete, end-to-end solutions (hardware, software, cloud, sensors, etc.)

- Security

- Funding the initial investment

- Determining the highest priority use cases

- Developing the business model

- Proving ROI

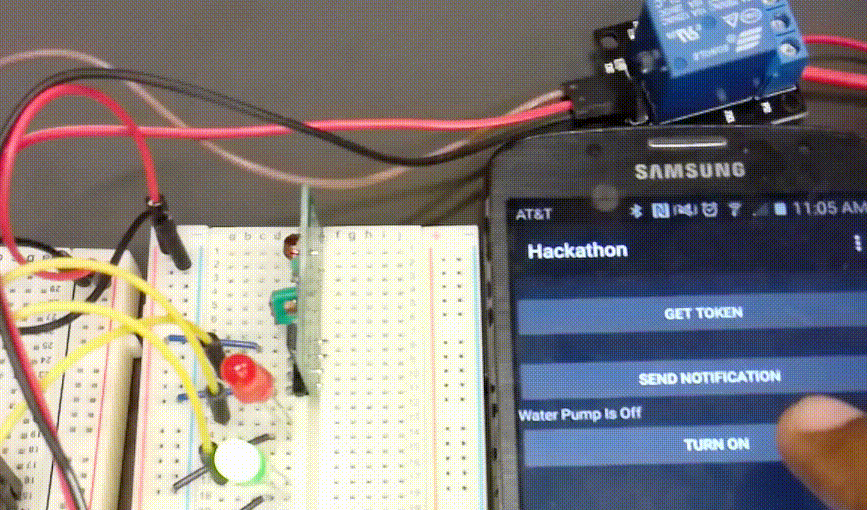

While there are many who consider the enormous volumes of data being generated and collected from IoT platforms as the key business case, most companies continue to struggle with developing an effective plan for making this data actionable. How can manufacturers deliver the data when, where and how it is needed by the respective user? The answer – with increasing connectivity, the mobile device is at the center of this new paradigm.

Manufacturers will need to think outside the box, or outside the walls of their plants, to truly understand IoT and adopt the benefits. A PwC survey found that only 30 percent of American manufacturing executives have plans to increase their IoT spend in 2018.

However, there are IoT apps available now with proven use cases. These include:

- Real-time Production Monitoring: minimizing waste and unnecessary work while improving operating efficiencies

- Product Quality Control: aligning product data with customer preferences

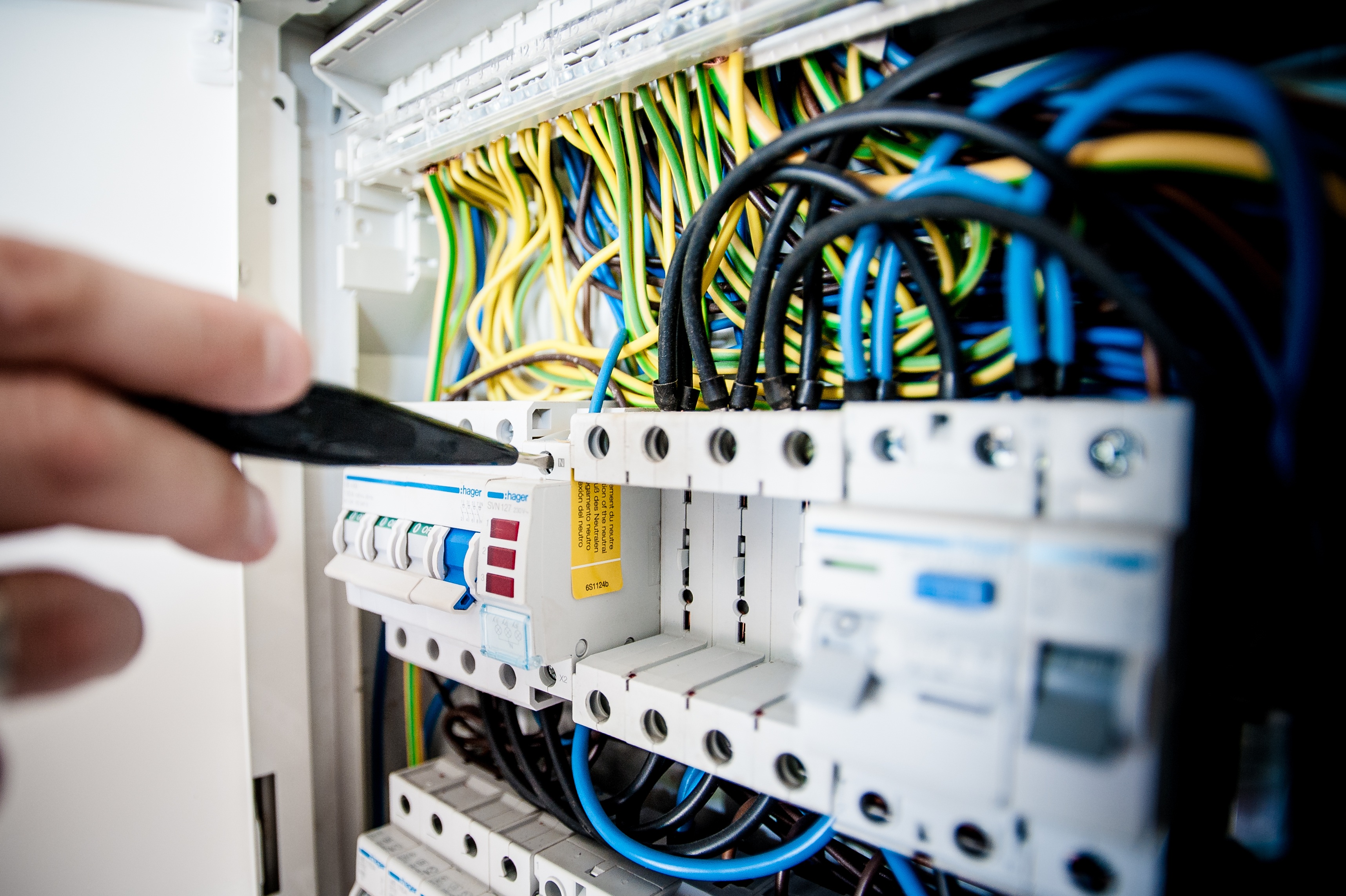

- Remote Equipment Monitoring and Management: temperature and air control; monitoring machine health and predictive maintenance to address repairs and avoid downtime before the equipment fails, and optimizing energy use

I recently had the opportunity to attend the MODEX 2018 show in Atlanta; it’s the largest supply chain show in the United States. The discussion regarding the integration of IoT and mobile devices related to use cases in the manufacturing sector was top of mind, from the exhibitor booths to the portable theaters hosting industry panel discussions. Some related topics from the MODEX show:

- Beacons tied to a particular location have been successfully used for a few years in conjunction with mobile apps in the restaurant, retail and travel industries. When a device that’s equipped with a specific app enters a defined geographic area, a beacon sends a signal as a notification or alert that initiates a process in the mobile app. This introduces unlimited use cases in warehouses and factories for improving efficiency and productivity

- Tracking and managing battery life on equipment such as forklifts and power tools, while also addressing the IoT needs of the battery manufacturers – transmitting data back and forth to be used for improving the performance of future battery products based on various operating conditions

- Connected fleet management for any type of vehicle that may be used in a manufacturing facility or for delivery. Forklifts, industrial trucks, or other vehicles embedded with sensors can leverage mobile devices to deliver analytics for route optimization and tracking, fleet performance metrics, anti-theft alerts, remote diagnostics/maintenance/control

The projections for the number of connected devices and equipment seems to increase by an order of magnitude every year. In 2016, Gartner predicted 20 billion connected devices by 2020. In 2018, that number is expected to exceed 50 billion devices by 2020, while generating a $19 trillion cost-savings and profit from this investment. Furthermore, of all the businesses who chose to implement an IoT solution, 94% have already seen a return on their investments.

So how do you start? For the novice, follow these simple steps to execute a successful mobile strategy for IoT:

Determine which users and personas will be using the data, then how to maximize the user experience by making the data actionable with mobile apps.

- Start small.

- Define what problem(s) you are looking to solve or process(es) to improve.

- Clearly define prioritized use cases and the related business cases for using connected products and apps.

- Decide what data you will need to capture and how it will be used on the backend, as well as how that data will be used to improve operations.

- Develop a trusted partnership with internal IT resources and third-party industry experts with hands-on experience.

The message to those sitting on the sideline – stop watching and do something. 2018 is your year.

Richard Banks

Richard Banks

Alexandra Tregre

Alexandra Tregre

Joe Conway

Joe Conway